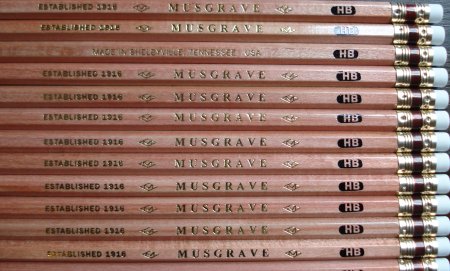

American heritage pencil maker Musgrave introduced a very interesting product in 2019: The Tennessee Red pencil. The pencil’s notable feature is the use of Eastern Red Cedar (Juniperus virginiana), the original American pencil wood. The pencil is very fragrant and visually interesting – each pencil is different, and many contain both cedar sapwood (pale colour) and cedar heartwood (dark colour).

The pencils are reminiscent of the old Musgrave HB in presentation, though the wood and lead are different. I found the Tennessee Red challenging to sharpen in a handheld sharpener like the M+R Pollux, with the lead snapping. Fortunately it is easily handled with the standard Grenade or a desktop sharpener. Still, the wood seems just a bit too tough for a pencil. I suspect this isn’t the fault of the timber – it is more that the slats just haven’t received the conditioning treatments to which we’ve become accustomed.

The lead is dark and rapidly crumbles. It certainly isn’t the quality of the old HB. It is perfectly usable, and I find this lead preferable to the anemic grainy lead of many no name pencils.

It isn’t a good pencil. Yet, it is unusual and compelling in multiple ways. I hope it will continue, perhaps with gradual improvements. In an unusually transparent act, the manufacturer has noted that the pencil has issues.

There are product reviews at Weekly Pencil and Pencil Revolution.

The Tennessee Red has a second aspect – it appears to be the subject of a small advertising campaign being conducted on Musgrave’s website and social media. The pencil has some nice new packaging including a cedar box option, and they are selling paraphernalia such as T-shirts.

Congratulations, Musgrave! It is really nice to see a new pencil being promoted.

To me, the most interesting aspect of this pencil is Musgrave’s disruption of the pencil supply chain. They have found a way to circumvent the cedar slat supplier CalCedar. Did you read the pencil’s imprint? “Genuine Eastern Red Cedar”. Wow. That is to me a very clear shot across the bow directed at CalCedar’s “Genuine Incense Cedar”. (They aren’t the first to rework this phrasing to make a point.) This pencil is also a statement about the pencil supply chain.

So how were these slats made? Perhaps pioneer fellow Tennessee manufacturer Wagner Pencil, who process American timber into pencil slats, gave assistance. Or perhaps Musgrave engaged with a wood processor not part of the pencil industry to create these slats. In any case, it is very interesting.

Private companies of course don’t reveal their internal business, but in some countries (including the US), there are public customs records that show import activity. Records from Import Genius show that in the last two years, Musgrave’s imports include:

| Item | source |

| Basswood Slats | Qingdao Greatwall (China) |

| Slats | Vinawood (Vietnam) |

| Erasers | Kunshan Greenwill (China) |

| Poplar Slats | Qingdao Greatwall (China) |

| Erasers and Ferrules | Shai Tai Shing (Vietnam) |

| Slats | Lishui Liancheng Pencil Manufacturing (China) |

| Slats | Pt. Gemilang Jaya Makmur Pratama (Singapore) |

From another perspective, Import Genius says that Musgrave’s top international suppliers (ranked by number of containers imported) are:

1. Tianjin Custom Wood Processing Co. (CalCedar’s Chinese production)

2. Great Wall Industrial Qingdao

3. Lishui Liancheng Pencil Manufacturing

4. Kunshan Greenwill Co.

Very clearly, this small town Tennessee company is highly engaged in the international economy. As the company notes, “… today Musgrave is able to work with a handful of different varieties of wood from all over the world.” Managing this complex supply chain must be almost as challenging as manufacturing the pencils.

Investing in and testing a historically proven local wood source is just savvy business sense. It benefits the environment and eliminates multiple containers from having to be shipped across the Pacific. For many reasons, local initiatives like this pencil from Musgrave should be supported!